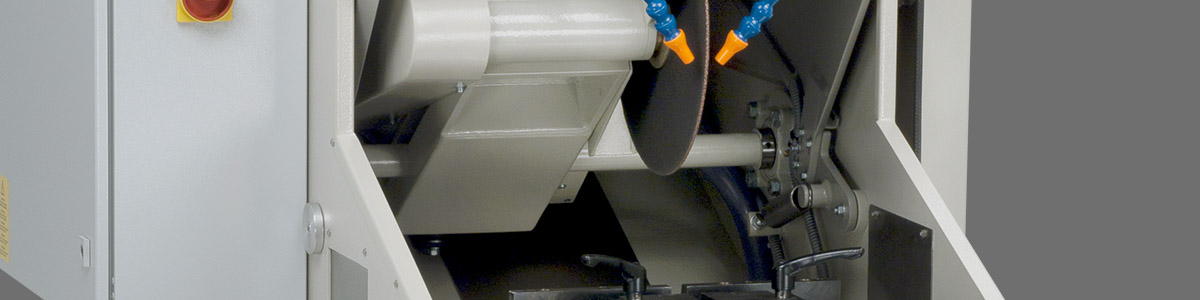

MSX305A Sectioning Machine: Automated Large Sample Sectioning of Hardened Materials

The LECO MSX305A Series is designed for sectioning large samples of many different types of materials using automated oscillation and servo-pulse sectioning. It is ideal for samples like induction-hardened parts, through-hardened tool steels, carburized pieces, and more. A manually adjustable Y-axis table provides easy sample position and parallel sectioning. Supports up to 14-in (350 mm) blades, and feature a powerful 10.05 HP (7.5 kW) motor and solid-steel construction.

Features

- Production-grade spindle supports up to a 14-in (~350 mm) wheel with 1.25-in (32 mm) arbor

- Welded-steel construction for the production environment

- Optional catch basket for capturing small, sectioned samples

- 15.75-in (400 mm) x 15.75-in (400 mm) T-slotted table with large sectioning compartment for versatile sample fixturing

- 30 gallon (115 L) built-in coolant tank with coolant fluid level gauge

- Sealed electronic enclosure and removable side ports

- Adjustment knob for sample feed

- Convenient, easy-to-operate control panel with 5.6-in (142 mm) dual-screen display

- Z-axis for manual sectioning (MSX305A1 Series)

- Joystick control for pulse sectioning (both MSX305A1 Series and MSX305A2 Series), blade direction, table direction, oscillation, and manual sectioning (MSX305A2 Series only)

MSX305A Details

- MSX305A1 Series

- Automatic, Pulse Servo Sectioning, with X- and Y-table

- 460V or 380-400V

- Automatic, Pulse Servo Sectioning, with X- and Y-table

- MSX305A2 Series

- Automatic, Z-Axis, Oscillation and Pulse Servo Sectioning

- 460V or 380-400V

- Automatic, Z-Axis, Oscillation and Pulse Servo Sectioning

- Catch Basket

- Laser Pointer

- Filter Fleece Blanket

- Sectioning accessories

MSX305A [PDF]

Explore Metallography Consumables